The stages of extracting the fragrance from flowers

How to extract the fragrance from flowers

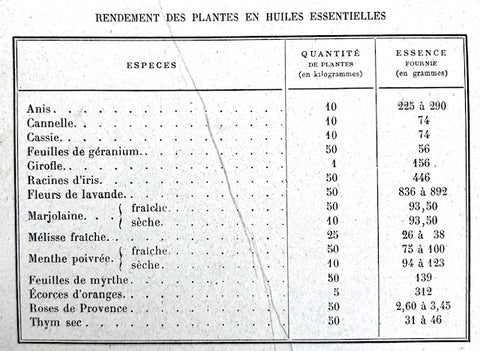

Extracting the fragrance from flowers, isn't it like imitating Prometheus, stealing fire from the sky! Is there anything more strange, more extraordinary, than the ability to capture the fragrance of flowers, that fragrant ether, which seems weightless to us and whose material reality may be doubted, as it is so subtle and seems akin to immaterial entities, such as genius or virtue, or to luminous or sonorous vibrations! And yet, no operation is easier or more prosaic in its manipulations, as we are about to see. The extraction of perfumes, essential oils - whose yield varies greatly depending on the plant that provides them, as shown in the table below - is done in different ways depending on the type of flower being processed and the nature of the essence desired.

The extraction by "expression" is only used with plants containing a large amount of essential oil: this method is used to obtain the fragrance contained in the peel (zest) of oranges, lemons, limes, and various other fruits. The process does not yield pure products, as the essence is mixed with water which needs to be separated later, a process that generally occurs spontaneously due to the difference in density of the two liquids, with one (the essence) floating on top. But it has the advantage of being done at a cold temperature, and the fragrances, not being subjected to the action of fire, retain great finesse. Expression by hand. It is not absolutely necessary to have a press to extract the essence from the zest: it is enough to squeeze it with the fingers; the secretory pouches burst, and the fragrance is released into the air.

To lose as little as possible, the pressure is applied between the fingers, near a sponge where the essence collects and can then be squeezed into a container; this method is often called the "sponge method." Bowl method. - A very simple apparatus can also be used, consisting of a bowl with spikes on the top and a hollow tube closed at the bottom. The worker holds the apparatus by the handle and, rotating it, ensures that the spikes scrape the skin of the lemons; the open cuticles allow the essence to flow out, accumulating in the lower tube. As it is detachable, the tube is removed; the result of the zest's shredding is poured into a container where the juice clarifies.

Presses for extracting perfumes

Screw presses. - Expression using presses yields more essence than the previous methods. Screw presses, of which various models are available on the market and can be operated by a single worker, can be used. The materials to be pressed are placed in fine hemp or horsehair bags, or better yet, in perforated buckets. The pressing should be moderate and progressive, increasing in strength as the resistance grows. The liquid flows into a container where it is left to rest and should be in enameled iron. Hydraulic presses. - Hydraulic presses, which allow a large quantity of materials to be processed at the same time, are only used in large operations.

Vertical presses are the only ones employed for perfume extraction. Extraction by maceration. Fat, and in general, all fatty substances have the ability to absorb the fragrance of flowers with great energy, to impregnate themselves with it, to extract it in a way from the organ that contains it. This results in a sort of ointment that can be used as is and from which the fragrance is then extracted using alcohol. Fat is mainly used when the plant is not very rich in fragrance. The process (see 213) is called maceration when liquid fat is used.

Preparation for perfume extraction

Purification of the fat: before any operation, it is good to clarify the fat planned to be used, in order to make it perfectly odorless. When a fresh fat is chosen, it is purified as follows: For 50 kg of fat: the fat is cut into pieces, then crushed in a stone or marble mortar. Once it is well crushed, it is washed and soaked in fresh water.

The washing is repeated three or four times until the wash water remains clear. Once this operation is completed, the fat is melted with 100g of powdered alum; it is boiled and skimmed for a few seconds. The melted fat is then strained through a slightly loose cloth, without exerting too much pressure on the residues; the marc is set aside for common ointments. The fat is left to rest in a large container for about two hours; then the clear fat is removed without leaving any water.

After the melted fat is clarified, it is cooked again with 3 or 4 liters of bran water and 150g of powdered benzoin, brought to a boil gradually, constantly skimming off the foam produced by the fat. After about an hour, when no more foam forms, the heat is turned off, and the mixture is left to rest for four or five hours, then strained into tin jars or basins, and the operation is complete.

Some pounds of fat are always left at the bottom to prevent any water from passing through; this material will be used for other purposes. The same method is used to purify beef fat. To prevent the fat from becoming too soft, which could lead to rancidity, 600g of pork fat and 28g of beef fat are added. In summer, the ratio is half and half. (Piesse.) Olive oil does not need to be specially prepared; it just needs to be well refined and free of the olive odor; neutralized oil is mainly used today. Extraction. - A certain quantity of clarified beef or sheep kidney fat, mixed with clarified pork fat as described above, is taken, placed in a clean metal or porcelain basin; it is melted in a water bath or steam.